MK4 Golf R32 Bespoke Mechanical Restoration

We had been having intermittent contact from this customer over a two year period, prior to the moment Andy finally took the plunge and commissioned us to carry out a full restoration to his R32 entire suspension, braking and running gear. In addition to this Andy was keen to have the timing chains, clutch, flywheel and entire exhaust system replaced. Then as a finishing touch to have us install a Racingline OEM+ remap.

Andy, in common with most of our customers, is a very discerning enthusiast who has researched his subject well and knows what his objective. We invited Andy to our workshops, to have a full sit down discussion over a cup of coffee, so that we could learn from him his requirements and we in return could explain how best we achieve these for him. With a plan in place Andy delivered his ultra low mileage Black R32 and we set about the upgrade works.

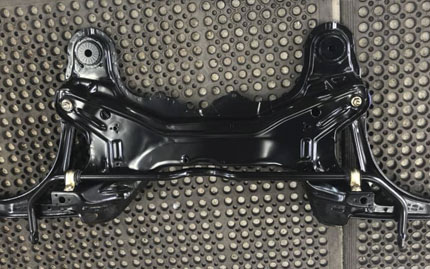

First phase was to drain all fluids prior to complete strip down. Out came the “old” exhaust, prop shaft, drive shafts, rear subframe assembly, front subframe assembly and suspension struts. These assemblies were then stripped down to component level and sorted according to the next process individually required, IE no longer required and to be disposed of or retained by customer, to be blast cleaned and powder coated, to be replaced by new components, to be presented to electroplaters for zinc and colour coating.

Whilst the removed components were receiving various re-finishing treatments. We got the orders in to our suppliers for numerous stock and upgraded parts. Amongst these was the full Milltek exhaust system, to include manifold and sports cats, and a very special request to our friends at KW Suspensions UK for a Variant 3 coilover kit in the Classic finish. Strictly speaking this option is not available for the Mk4 Golf, however, As has been said Andy is discerning and having seen this kit option on a Corrado we were working on, he had to have this on his R32. I must say i agreed with his thinking and on a black R32, the KW Classic V3’s would look fantastic. Thankfully Richard Good at KW UK agreed too and JMR as Performance Partners with KW UK we were given the concession to go ahead with this kit.

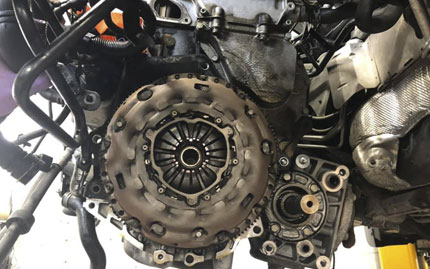

With the powder coating and parts order still incomplete, we used this time to set about changing the timing chains, clutch, flywheel and other service related works in the engine compartment. This was also a good time to fit the manifold sections of the Milltek exhaust, with the transmission out of the way. This was also the moment we used to prep, blast clean & clear lacquer seal the outer castings of the rear diff and Haldex, to include new filter, oils, and a new earth cable.

As soon as all the powder coated parts, electroplating and new parts were ready, it was time to begin assembly. All four driveshafts were fitted with new boot kits and were rebuilt onto the powder coated shafts. The front and rear hubs were fitted with new wheel bearings. The front and rear subframe assemblies were rebuilt with all new bushes, mostly stock rubber, but with poly bushes into the front lower arm rear position. Andy had wanted all poly bushes, however, we explained that this would have given a very harsh ride quality and indeed there was no need for such, as indeed the KW V3’s would vastly improve ride performance and compliance alongside stock anti-roll bars. The rear subframe assembly was next and this would incorporate the rear diff. The propshaft was reassembled post refurb and this left only the KW kit to be preset on ride height as post fit prep.

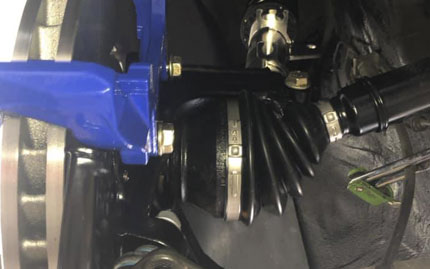

The running gear was offered back up onto the chassis, starting with the KW Classic kit, next the subframes assemblies, front shafts and propshaft. Lastly the braking system was reassembled onto the car. The callipers we had previously prepped and powder coated the same OEM shade of blue for the R series. New brake discs and pads all round and by the end of this session, we very nearly had a complete car once more. Just the new Milltek Sport Cats and cat back system to fit and align.

Building now for the final phase, all the fluids were refilled IE engine oil, gear oil, coolant, power steering fluid and hydraulic fluid. Once the brake system was satisfactorily pressure tested the re,furbished and powder coated R32 alloys were re-fitted to the vehicle, but not before being re-shod with new Hankook EVO2 tyres. We were now ready for engine start and on ramp testing of all works carried out. All went well, as expected, so the R32 was transferred to our four post alignment ramp, where the initial ride height was confirmed, before the wheel alignment and geometry was set. Next was time to test drive this fresh built setup. This helps to settle the new suspension as well as confirming all other settings. Back to the workshop to make final adjustment tweeks to the KW Variant 3 bump and rebound valving, before a final confirmation drive.

Finished and ready to call Andy, who we know is busting at the seems to drive his rebuilt R32. Andy took the car out for a long drive before returning home. On his return to the workshop one could see instantly his delight with our work and the all new ride quality and compliance. Another happy customer and a great guy to do business with. We look forward to Andy joining us at shows into the New Year 2020 season.

Workshop - 01903 718684

Mobile (Working hours only) - 07974 020031

Hours of Business:

Monday - Friday: 08:00 - 17:00

Saturday - Sunday: Closed

JMR Ltd (John Mitchell Racing), Units 14 & 15, Arunside Business Park,

Fort Road, Littlehampton, West Sussex, BN17 7QU

We recommend that you approach our premises from the A259. Enter into Lineside Industrial Estate at the new traffic light junction with Eldon Way, and follow signs for Fort Road. You will be directed by signs down Arndale Road past the Builder Centre, through an “S” bend and onward to a “T” junction. At the “T” Junction turn right onto Fort Road keep going straight down until you reach a large yellow security gate. This is Arunside Business park in which we are located. There is a site map at the entrance above the yellow gate, but the site is very small and a single one way road will take you directly to our premises.