JMR Built Corrado 2.0 TFSI CDL S3 / 6Spd

Part 1

This was a very special commission, customer build project, with every aspect of the build having a specific instruction. This car had to be at home on country roads, fast open motorways, have a comfortable bespoke interior with elements of current tech, have a modern engine and gearbox able to deal with changing fuel specification and emissisions, whilst at the same time retain it’s modern Classic styling.

A big build brief and we were right up for the challenge.

The first step was to locate and purchase the cleanest possible donor Corrado, on which to base the build. Our customer took on this task and very quickly found the ideal donor, a 1989 Corrado 1.8 16V which had the cleanest, original, corrosion free body I have seen on a Corrado for some time.

The donor was stripped to a bare shell, leaving only what was required in position for us to offer up the TFSI engine and 6 speed gearbox into position and fabricate the mountings into the chassis legs.

Next, the shell was off to the bodyshop for total inside / outside repaint into a non-Corrado colour, but from the Volkswagen line up, Bottle Green. Whilst at the bodyshop the bare shell was mounted onto a spit so the floor pan coukd be prepped and painted with satin black Raptor finish. This is a great product, as it gives extraordinary wear and looks fantastic. It also is a wipe clean surface to keep everything looking good as the day it was applied.

Step 2

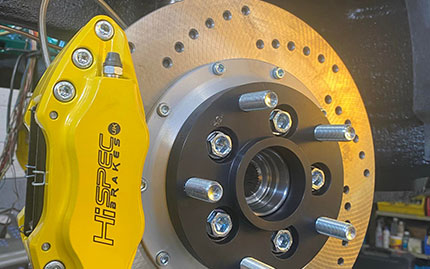

Back at the workshop, post repaint, the long task of building the Corrado from bare shell began. A rolling shell was established, installing all freshly powder coated running gear, rebuilt with all new bushes and re-plated hardware. KW Classic Variant 3 coilover suspension was installed, along with four pot front brake upgrade and improved rear brake callipers. The customer had chosen Porsche DT90 16” wheels and these were fitted to the VW hubs with KW ST hubcentric spacers and studs in place of wheel bolts.

Next up we laid in the wiring harnesses for the main vehicle functions and then installed all the other supporting features within the engine compartment, made all the more accessible by the engine not being fitted yet.

The TFSI engine and gearbox were next. The engine we had already prepared, while the chassis was at the bodyshop. The engine had a new K04 turbo, cam belt kit, water pump, cam timing chain and tensioner, HPFP and cam follower, new throttle valve 0plus many more components to ensure it was goid for many miles to come. We also took the opportunity to carry out a full inlet port clean with the specialist equipment we have, to remove the typical carbon deposits accumulation on the inket ports and valves. At the same time we cleaned and fliw tested the fuel injectors and had them fitted with replacement upgrade internal metal basket filters. The plastic OEM filters break up and cause injector failure in the for of poor operation. The gearbox we rebuilt and fitted a Quaife ATB limited slip diff to help with the increase power through the front wheels.

The engine and gearbox were installed onto the custom made new mountings on the inner wings, as opposed to the subframe mounts as per the OEM Corrado specification. All supporting parts were then installed. Including custom length front drive shaft with uprated CV joints. Fitted at this stage was one of our EPAS electric power steering columns, a variant of what we developed for my Corrado 2.0 16V Turbo 4WD. In addition to this a custom made 3” stainless steel exhaust system was fabricated and installed.

Now for the engine management system and total re-wiring of an all new engine harness. We were originally planning to use the OEM TFSI ECU, however, this involves having to use the factory harness and numerous canbus controllers and power supplies. All if these factors make for a very bulky build and leave little access in the engine compartment for future service works. We elected therefore to go out on a limb and cut an all new path, we use our preferred ECU for which we are recommended Dealers. A Link GDi was fitted along with key Link supporting components. This ECU fitted easily into the vehicle plenum using a Corrado G60 mounting plate. The wiring of this ECU was a bit of a mission as indeed it had not been completed before and therefore we had to work through many aspects of the install.

Step 3

The interior was next and therefore the Corrado was delivered to our specialist of choice Trim Deluxe, who carried out a bespoke installation using custom front seats, and Singer Porsche platted leather. Many bespoke features were incorporated into this interior and this of course included the ICE installation completed by our good friend Jeremy at Highdown Car Audio, who constructed a custom fit sub box into the rear boot compartment, complete with underfloor storage spaces and spare wheel.

Location, also the use of the Blaupunkt Bremen head unit to keep everything looking classic, but still having DAB radio and connectivity with phones etc.

Back at the workshop the final prep was made for rolling road mapping of the ECU, before loading onto our trailer and driving to DC Automotive. The actual mapping of the Link GDi to the TFSI was again requiring a little more thought as we were breaking new ground, however, all went well and the map delivered a really smooth progressive power delivery with a very agreeable 275 BHP. Perfect for this customer’s requirements and still with plenty more power if required later, of up to 310 BHP with a clutch upgrade. Always nice to have more power options for later use, once you get used to the initial output.

The final phase of works was really all about getting formalities like MOT sorted, which happened with ease, as indeed this is in many respects a new build. We put 200 plus miles of test driving into this vehicle, to ensure every aspect of the build was good. Both Ben and me found this Corrado to be a joy to drive. Excellent road holding, smooth progressive power delivery, indeed effortless is the word. Comfortable cabin with enough GT sounds to let you know what your doing, but not in any way obtrusive to comfort. You could drive long distances with ease in this Corrado and get out fresh on arrival. Handover day followed and Rob was delighted with every aspect of his custom built Corrado. In his words, “it delivers in every department”.

Workshop - 01903 718684

Mobile (Working hours only) - 07974 020031

Hours of Business:

Monday - Friday: 08:00 - 17:00

Saturday - Sunday: Closed

JMR Ltd (John Mitchell Racing), Units 14 & 15, Arunside Business Park,

Fort Road, Littlehampton, West Sussex, BN17 7QU

We recommend that you approach our premises from the A259. Enter into Lineside Industrial Estate at the new traffic light junction with Eldon Way, and follow signs for Fort Road. You will be directed by signs down Arndale Road past the Builder Centre, through an “S” bend and onward to a “T” junction. At the “T” Junction turn right onto Fort Road keep going straight down until you reach a large yellow security gate. This is Arunside Business park in which we are located. There is a site map at the entrance above the yellow gate, but the site is very small and a single one way road will take you directly to our premises.